In the 1960s, CNC plasma cutting equipment developed strongly in the mechanical industry. Widely used and used as an effective tool for metal cutting. So what is plasma? What is the composition of a plasma? What is the advantage? The following article, will share useful information for you to better understand Plasma.

Plasma is the fourth state of matter and plasma is the first state in the universe, in nature plasma is the phenomenon of lightning, in which substances are strongly ionized and become electrically conductive due to the state change process. to another state through the effect of heat.

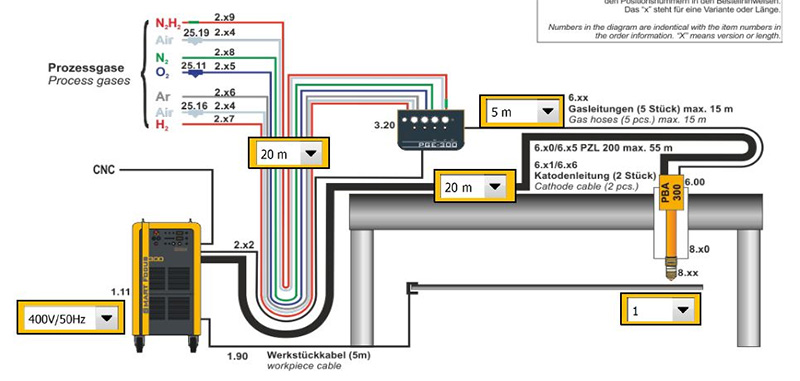

Structure of Plasma cutting machines

Structure of CNC Plasma cutting machine

Plasma cutting machines are now available in Vietnam market. Including 2 types of plasma cutting machines for customers to choose: manual plasma cutting machines & automatic plasma cutting machines.

- Manual plasma cutting machines: These machines are mainly controlled by manual handles.

- Automatic plasma cutting machine: This type of machine is controlled by high technology.

However, a simple plasma cutter system always includes: Power supply unit, arc start circuit and cutting head.

When plasma cutting begins, plasma-forming gases such as nitrogen, argon, hydrogen, oxygen, inert air, etc. Through small holes in the plasma nozzle, an electric arc is generated from the external power supply. and soon into the gas source with great pressure; this makes it possible for up to 40,000 degrees Fahrenheit to pass rapidly through metal melting plates; puncturing the workpiece at high speed resulting in molten material from the cutting edge; Right now the cutting head starts moving and the cutting process occurs.

Advantages of Plasma cutting machines

- Fast cutting speed to increase productivity, reduce the overall cost of the product.

- Cut a variety of materials with different thicknesses and cutting thickness can be up to 80mm.

- Simple to use without high technical requirements, easy operation and operation without much adjustment.

- Creating a small amount of scrap to save materials.

- The cutting surface is more precise and cleaner, so there is no need to rework, improve machining costs and do not waste time cleaning.

- Splashes plummeted compared to conventional mowers.

- Less slag creation, high equipment life.

With the above knowledge we hope that you will have a lot of useful knowledge about plasma cutting machines.

When you need technical advice and welding methods, please contact us for advice and specific instructions to help you choose for yourself a product of technical standards along with price. reasonable.