- 100% new machine manufactured by Thien Long Solution Company Limited.

- Dragon welding robot - 3009 is a robot using Cartesian coordinates to help simplify mechanical parts to improve the lifespan and accuracy of the robot, including 4 X, Y, Z, A coordinate axes. servo helps the shaft to move quickly, flexibly, accurately, without pulse loss.

- The shafts move by gear bar, gear, ball screw for fast movement with high precision

- Using dedicated controller for industrial welding robot with high durability and stability

Technical parameters:

|

No |

Part |

Amount |

Unit |

Description |

|

1 |

Robot Dragon-3009 |

|

|

Commonly used in the industrial manufacturing industries: Frame welding robots, Bed welding robots, Scaffolding welding robots, Furniture welding robots, Car welding robots, motorcycles ... |

|

2 |

Robot size |

|

|

3500x 1300x1800mm |

|

3 |

Useful weld size: |

|

|

3000x900x800mm |

|

4 |

X axis control system |

first |

The set |

Moving the torch along the robot body: using Servo motor with controller, planetary gearbox, gear. |

|

5 |

Y axis control system |

first |

The set |

Horizontal welding torch traverse of robot: Servo motor with controller and planetary gearbox, gear. |

|

6 |

Z-axis control system |

first |

The set |

Moving the torch in the vertical direction of the robot: using the Servo motor to move the torch up and down with Vitme ball system, TBI square slider. |

|

7 |

R axis control system |

first |

The set |

Rotate the torch around the shaft: use a servomotor, gearbox crystal. |

|

8 |

Electrical cabinet components |

first |

The set |

|

|

Using components Omron, Siemens, LS ... |

||||

|

9 |

TBI TR20 square track |

5 |

Meters |

TBI square rails help guide the X axis precisely and ensure durability for the machine. |

|

10 |

TBI TRI 5 square rails |

5 |

Meters |

TBI square rails help guide the Y, z axes |

|

11 |

Proximity sensor |

7 |

The |

Use limited Autonic sensor, protect the shaft. |

|

12 |

Welding mode |

|

|

Using MIG / MAG, TIG welding methods. |

|

13 |

Automatic stainless steel wire feeding system for TIG machines |

first |

The set |

Automatic stainless steel wire supply for TIG machines (Useful in case of open joints) |

Requirement of the condition where the machine is installed

|

No |

Request |

|

1 |

The user should make the cement base |

|

2 |

Power supply: (1) 3 phase 380V ± 10% / 50Hz, single phase 220V ± 10% / 50Hz (2) Three-phase voltage phase displacement: <2.5% (4) Using a voltage stabilizer will be more stable Note: Ground resistance <10 Ω |

|

3 |

Working temperature: -10 ° C - 45 ° C Air humidity: <90% Surrounding environment: well-ventilated, not strong shaking |

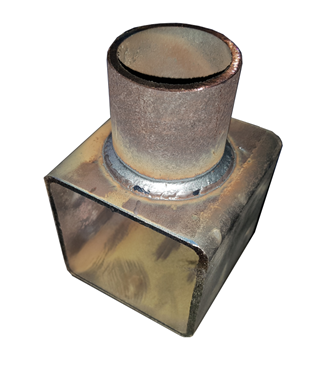

Product photos

Video:

<